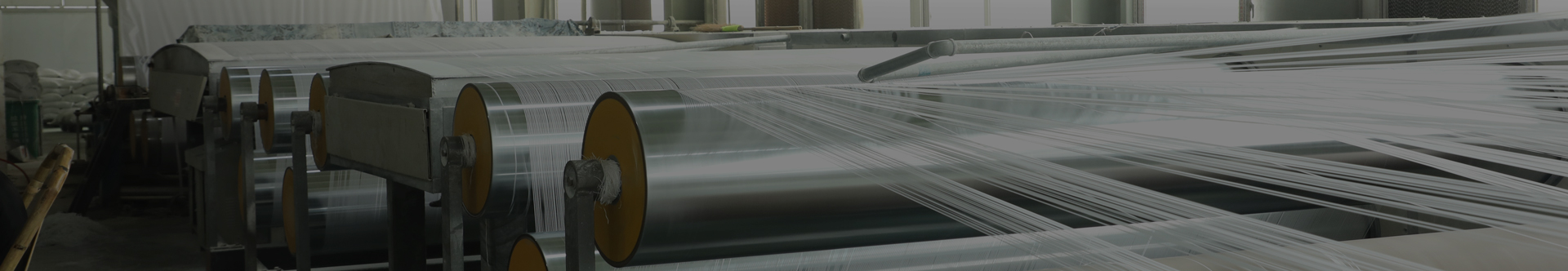

Mekotla ea polasetiki ea polasetiki e entsoe ka polypropylene (PP) joalo ka thepa e tala ea mantlha, e fetisitsoeng, e huloang ka tšepe, e lohuoa bocha, e lohiloe, 'me e entsoe ka mekotla ea ho paka.

PP ke polasetiki e bonaletsang, ea semi-crystalline thermosetting e thata haholo, thepa e ntle ea ho kenya letsoho, ho monya metsi a tlase, mocheso o phahameng oa tikoloho, letsoalo le tlase le lekanyelitsoeng, le mocheso o phahameng oa khalase.Ke thepa e ka sehloohong e tala bakeng sa ho etsa mekotla ea ho paka.Lisebelisoa tsa li-filler tse fetotsoeng hangata li kenyelletsa likhoele tsa khalase, lisebelisoa tsa ho tlatsa liminerale, rabara ea thermoplastic, joalo-joalo.

Sekhahla sa tšebeliso ea mekotla ea polasetiki e pharalletse haholo.Mothating ona, lits'ebetso tsa mantlha tsa mekotla ea polasetiki ke ho paka kantle ho lihlahisoa tsa temo, sephutheloana sa kantle sa mekotla e lohiloeng ea polasetiki, lisebelisoa tsa ho paka lijo, boenjiniere ba jeoloji, lipalangoang tsa bohahlauli ba matsatsi a phomolo, ntoa ea likhohola le lisebelisoa tsa tšohanyetso, joalo-joalo. mefuta e meholo ea mekotla ea ho paka: mekotla ea polasetiki (mekotla e se nang lifilimi), mekotla ea polasetiki e kopantsoeng le mekotla e fapaneng e lohiloeng.Mokhoa oa tlhahiso ea mekotla ea polasetiki ke: mekotla e lohiloeng e fetoha mekotla ea ho paka ka mor'a ho paka le ho hatisa, ho itšeha ka laser le ho roka.

Ho ipapisitsoe le mochini le lisebelisoa tse sebelisitsoeng, e ka khaoloa ka laser ebe ea hatisoa, kapa ea hatisoa ebe e khaola laser.Mochini oa ho roka oa othomathike oa laser o ka ntšetsa pele mokhoa oa ho paka khatiso, ho itšeha ka laser, mochini oa ho roka, joalo-joalo, hape o ka etsoa ka lipokothong tsa li-valve, lipokothong tse tlase, joalo-joalo. mokotla o ka etsoa.Ts'ebetso ea tlhahiso ea mekotla ea liphutheloana tsa polasetiki e kopantsoeng ke ho sebelisa mekotla e lohiloeng, majoe a kopantsoeng kapa lifilimi bakeng sa poelano kapa ho roala ka motsoako.Lirolo kapa maqephe le lirolo tse fumanoeng li ka khaoloa ka laser, tsa pakoa le ho hatisoa le ho rokoa ka opereishene ho etsa mekotla e ka tlase ea seam.Ba ka boela ba bula masoba, crimping, ho itšeha ka laser, khatiso ea liphutheloana, ho roka ka ho buoa le mekotla e lohiloeng ka polasetiki.Letlapa le fumanoeng le ka khomaretsoa ka seam, khatiso ea liphutheloana, ho itšeha ka laser, ho tlama sekoahelo le mokotla oa ho peista.E ka boela ea chesetsoa, ea behoa, ea crimped, ea etsoa ka li-sheds tsa lehong le li-geotextile tse sa lohiloeng.Li-flat looms li ka ba tse pheta-phetoang kapa tse sa phete-phetoang le tlhahiso, li-geotextile tse sa lohiloeng, joalo-joalo Lesela la drum le ka boela la hlahisoa khafetsa kapa che.

Matšoao a ts'ebetso ea ts'ebetso ea tlhahiso ea mochini oa terata ea polasetiki e arotsoe haholo ka mekhahlelo e mene:

1. Boleng ba index ea tšebetso ea 'mele.Haholo-holo ho na le liphoso tsa li-unit tse kang matla a ho robeha, matla a ho senya, matla a ho tsitsa, lebelo la angular, le density;

2. Index ea boleng ba thepa e fetotsoeng ka lik'hemik'hale.Haholo-holo e kenyelletsa ho kopanya lisebelisoa tse fetotsoeng, ho kopanya ho itokisa, ho eketsa karo-karolelano ea li-modifiers, le karo-karolelano ea litšila tse nchafalitsoeng ka manyolo a kopantsoeng ke granular;

3. Dimensional tolerance specification index value.Haholo-holo e kenyelletsa botenya ba mochini oa ho taka oa terata ea polasetiki le bophara ba terata e bataletseng.

4. Thepa ea 'mele boleng ba index ea rheological.Haholo-holo ho na le karo-karolelano ea likhoele, karo-karolelano ea inflation, karo-karolelano ea moralo le karo-karolelano ea shrinkage;

Theknoloji ea ho lokisa mekotla e nang le lined Thepa e phahameng ea khatello ea polyethylene e futhumatsoa ke extruder, e qhibilihisoa 'me e ntšitsoe hantle;

Tobetsa polasetiki e bōpehileng joaloka barrel ka filimi ea polasetiki e bōpehileng joaloka moqomo;kena ho fokotsa lerōle le fofang le ho baka li-bubble tsa tube;

Sekhahla sa ho otlolla moriri se bōpehileng joaloka herringbone se pholile 'me se bōptjoa ke selikalikoe sa moea o pholileng,' me ho ts'oaroa ho tlisoa phetohong;

The drive system rolara e huleloa ho matsoelintsoeke rolara ka traction lebanta rolara;

Qetellong, ho itšeha ka laser ho etsoa, mokotla oa lesela o hlahisoa ke mokhoa o chesang oa ho qhibiliha, 'me qetellong litholoana li kenngoa ka mokotla.

Polypropylene e hloekileng ha e khone ho fihlela litlhoko tsa mechini ea ho taka ka terata ea polasetiki, empa hape e hloka ho eketsa peresente e itseng ea polyethylene, calcium bicarbonate le colour masterbatch.Ho eketsa palo e nyane ea polyethylene nakong ea ts'ebetso eohle ea extrusion ho ka fokotsa viscosity le sekhahla sa ho qhibiliha ha phallo ea thepa, ho ntlafatsa mokelikeli, ho ntlafatsa ductility le ho feto-fetoha ha mochini oa polasetiki oa terata le mekotla ea ho paka polasetiki, ho boloka matla a itseng a thata, le ntlafatsa ts'enyo ea mocheso o tlase oa polypropylene.

Li-additives tse ntlafalitsoeng tsa polypropylene li ka fokotsa mocheso le khatello ea ho sebetsa libakeng tsa tlhahiso le ho sebetsa.Ntlafatsa phallo ea data le ho khomarela, ntlafatsa matla a tsitsipano.Ho eketsoa ha calcium bicarbonate ho ka fetola mefokolo ea ponaletso e felletseng le opacity.Ka ho fokotsa ho otlolla, ts'ebetso eohle e kotsi ho induction ea electrostatic kaha e kotsi ho khohlano, ho ntlafatsa ho khomarela enke ea khatiso bakeng sa ho paka le ho hatisa li-logos tsa matšoao, ho fokotsa pokello ea tlhaho le litšenyehelo tsa taolo ea lihlahisoa tse felileng nakong ea polokelo.

Nako ea poso: Jun-29-2022